In addition, they were the only compact industrial platforms that could be retracted and fit into the corner of the room.

Ultimately, the use of scissor lifts for practical and functional purposes have increased. Modern scissor lifts maintain a presence in nearly all aspects of manufacturing and production, from construction to assembly to vehicle repair and beyond.

Newer models can travel over the smooth surface of the airport, shopping mall, warehouse or hypermarket floors, for example Optimum 8 that does not leave behind tyre marks, or the uneven terrain of a construction site, for example Compact 10 DX.

Scissor lifts can also be custom made. We can see heavy duty scissor lifts in many industries and can even withstand harsh temperature environments.

In the energy industry, massive scissor platform lifts are used to assemble large energy turbines.

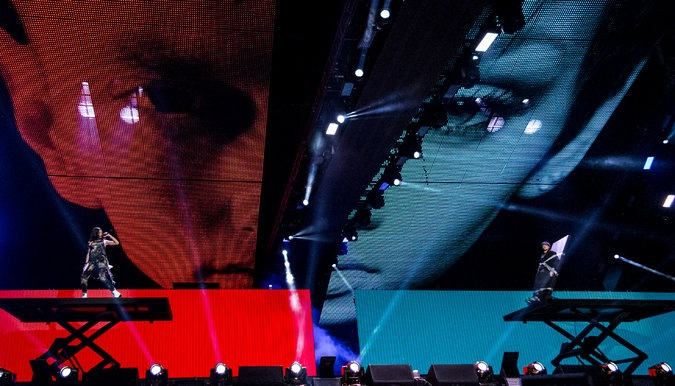

The use of scissor lifts can also be found in the entertainment industry. In action film productions, there are many stunts and special eff ects to be considered. Besides using the aerial boom lifts, cameramen would use the scissor lift for better aerial shots.

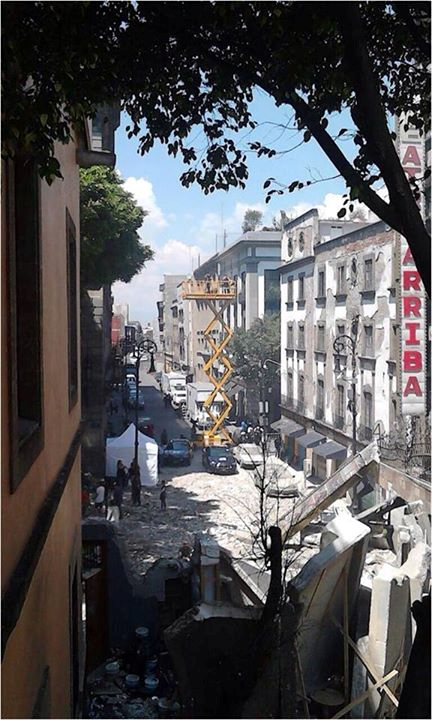

Recently, our H 15 SX had been used for a movie production in Mexico City; James Bond Spectre which is scheduled to be released on 6 November 2015.