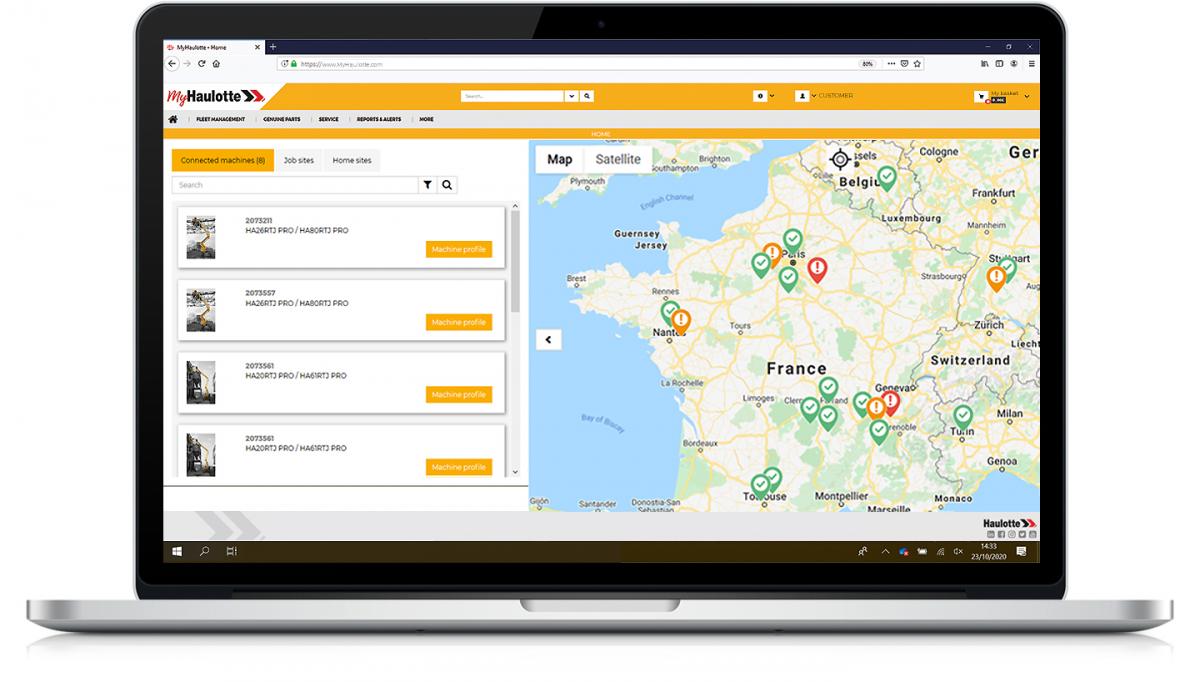

Haulotte has recently launched their newest technology SHERPAL, a fleet management solution that has now started to be installed on several machines in Australia. Over 250 Coates Optimum 8’s have already had the telematics solution installed with more to follow.

Monitor your fleet from anywhere, in real-time

- the machines’ operational status in real time,

- the machines’ hourmeter and next maintenance deadlines,

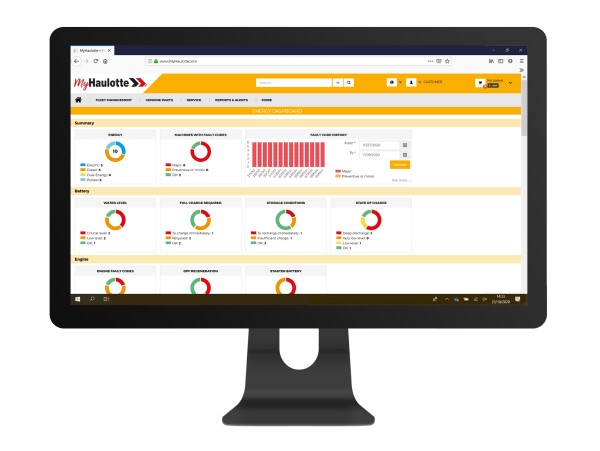

- engine and battery status,

- fault codes, root causes, and even instructions on how to fix the problem

Dan Goodfellow, Group Manager - Products for Coates

SHERPAL is enhancing fleet safety and health

With a focus on safety, SHERPAL can also identify risky behavior and send an alert in case of entrapment or overload situations. Monitoring hazardous machine use and occurrences makes it easier to implement appropriate safety policies on the jobsite.

Scheduling and repairs made simpler

SHERPAL drives business growth

The permanent record provides better insights to improve the equipment’s uptime. By analysing them, it is possible to identify underutilised machines. Usage, fault, and maintenance history are also very helpful to enhance the equipment resale value. The operator benefits with data from the basket including weight and working height recorded.

Two ways of accessing telematics data